Glazing Ratio - How it's Calculated

This article explains how we generate the recommended glazing ratio scores in the PreDesign Glazing Ratio feature. Specifically it explains:

- Overall philosophy and use of ASHRAE 90.1 as inspiration.

- How we determine a maximum recommended ratio for cold weather.

- How we determine a maximum recommended ratio for detrimental sun.

- How we combine the above considerations.

Generally speaking, our recommendations mostly look to ASHRAE 90.1 (2017) for inspiration and assume the designer is seeking equivalent performance to a baseline building facade.

Related articles:

Strategy Scoring

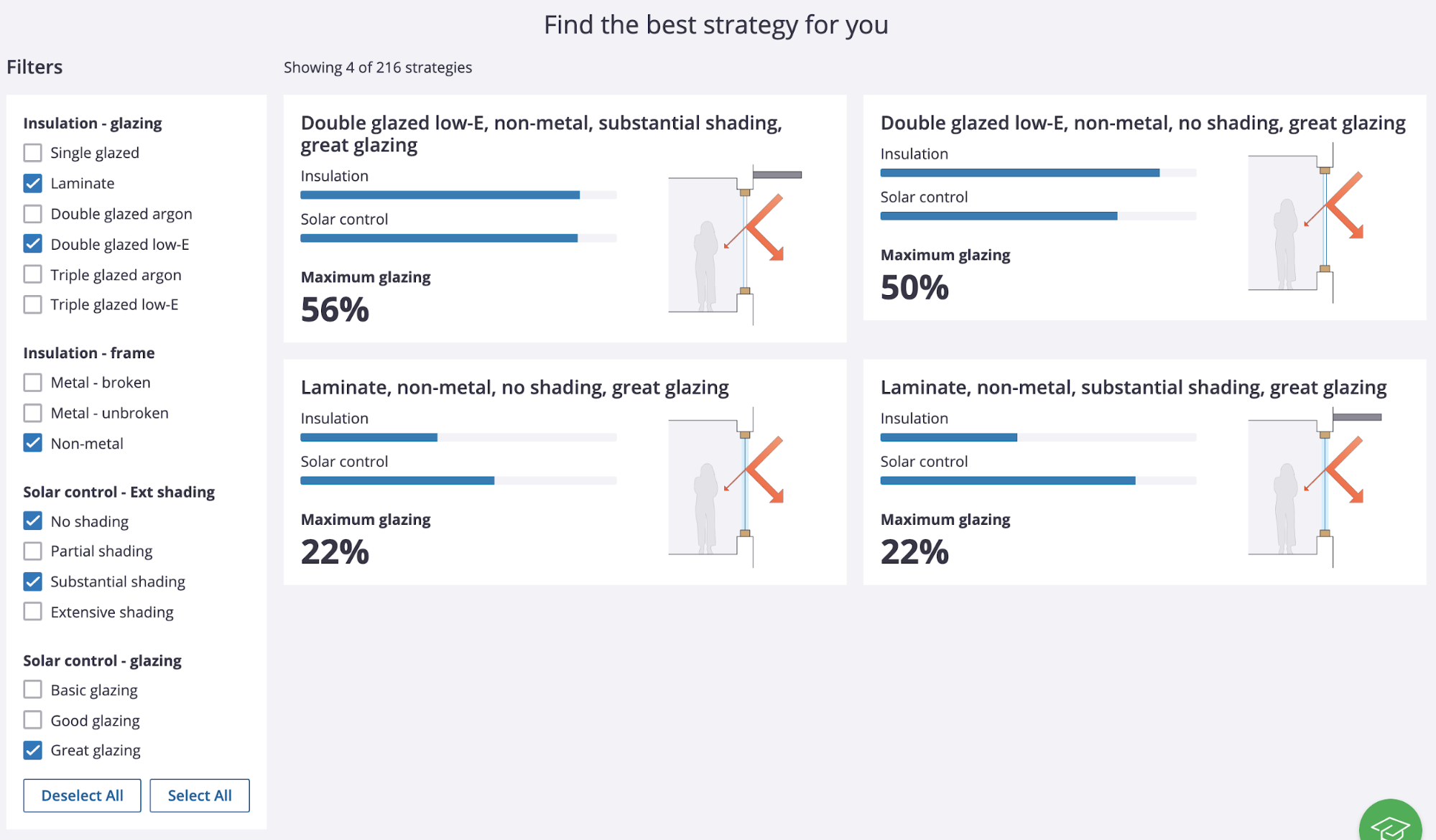

In the Glazing Ratio feature, each strategy is given a score with a recommended maximum glazing ratio, shown as a percentage. See below for an example - the 4 strategies here have maximum ratios ranging from 22% to 56%. Note the options are always ranked highest to lowest in the way they are presented.

Feature design philosophy

The ASHRAE 90.1 standard incorporates a method where the designer creates a baseline version of their design and then compares a proposed design against the baseline.

If the proposed design is at least as good as the baseline, then the standard has been "passed". Usually this is done with a full energy calculation, but of course at PreDesign, we don't even have a 3D design and we probably don't have anyone around who can do energy calculations!

So the idea is that this feature looks at what would be equivalent in performance to an ASHRAE 90.1 baseline. The recommended maximum glazing is therefore the amount of glazing you could have that would be equivalent to the baseline model performance (all other things being equal).

We do this broadly as follows:

- We work out the ASHRAE climate zone for the study based on the location you entered.

- We work out what the baseline model facade overall insulation values would be according to the standard and then derive glazing ratios for different combinations that would be equivalent to this.

- We work out what the baseline model facade solar control would be in terms of a whole facade equivalent solar heat gain score and then look at how shading and glazing combinations would achieve an equivalent outcome.

- We then compare the two above and work out which one is the driving constraint on glazing ratio and that becomes the maximum recommended value.

How it works in cold weather

We use the standard to find out 3 values for the baseline model we compare against:

- What the baseline model glazing ratio would be (this is set at 40% for all options)

- What the baseline model glazing assembly U-value would be (ie how insulated is the window system as a whole)

- What the baseline model wall assembly U-value would be (ie how insulated is the wall system as a whole).

These values vary by building type and by climate zone. For cold weather, orientation makes no difference. In climate zones where there is no winter, we ignore this consideration.

We then work out an effective baseline U-value for the entire facade assembly.

We then look at each strategy. We firstly determine:

- The strategy's glazing assembly U-value (based on frame and glazing type). This is calculated using LBNL's Window 7 software and all assembly options are available on request.

- The strategy's wall assembly U-value (we assume this is the same as the baseline model).

Using these two values and the known "whole facade assembly U-value" of the baseline, we work backwards to determine the % of glazing for the proposed strategy that would achieve the same "whole facade assembly U-value". This becomes the insulating maximum glazing value (a percentage).

How it works for direct sun

In working out how direct sun should affect how much glazing is used, we first look at each orientation and try to determine whether or not the facade has a direct sun problem.

This is done in the same way we work out whether or not shading is recommended for that facade, which is described in full elsewhere.

In short, we do the following:

- Consider the Balance Point Temperature (based on the building type).

- Describe the time-step as "overheating" if the outside temperature is at least 2°C above the Balance Point Temperature.

- Modify the effective outside temperature up further if the sun's radiation is of a high intensity.

- Determine the difference between this effective outside temperature and the balance point temperature.

- Modify it again based on the angle of incidence of the sun on the facade at that time.

- End up with a "degree-hours of overheating" value for that time step.

- Add up all the "degree-hours of overheating" values to determine the total number over the whole year.

This number then needs to be above a threshold for the facade to be considered to have a direct sun problem. (see table below)

If we conclude there is a problem, then we proceed to the next part of assessment. If not, direct sun is not considered a factor for that orientation in determining glazing ratio.

If direct sun is considered to be a problem, we use the standard to find out 2 values for the baseline model we compare against:

These values vary by building type and by climate zone. Orientation makes no difference here. Then we do the following:

- We use these to work out an effective baseline SHGC for the entire facade assembly.

- We then look at each strategy and determine the effective glazing SHGC based on the glazing solar control (which essentially describes an SHGC).

- We modify this based on the shading type used as follows:

- Reduced down by 0% with no shading

- Reduced down by 25% with partial shading

- Reduced down by 50% with substantial shading

- Reduced down by 75% with extensive shading

- The strategy's whole facade glazing assembly effective SHGC is then obtained and examined in combination with the baseline effective facade SHGC.

Using these two values and the assumption that the opaque facade has an SHGC of 0%, we work backwards to determine the % of glazing for the proposed strategy that would achieve the same "effective facade SHGC" as the baseline. This becomes the solar control maximum glazing value (a percentage).

Reference tables

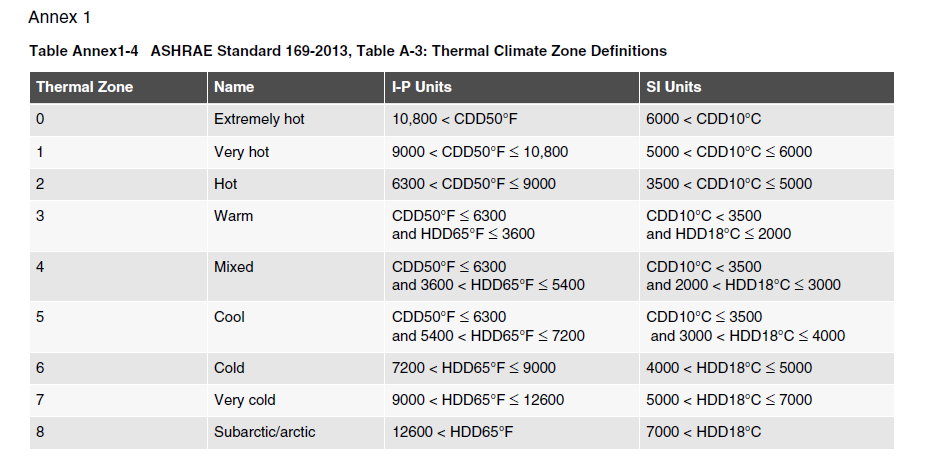

The following tables provide look-ups for the baseline values used in the calculations.Climate zones

Calculated from ASHRAE Standard 169-2013. See table below.

Baseline Properties

U-values for Glazing and Wall assemblies and baseline SHGC for glazing (from ASHRAE 90.1 (2019)

| Non-residential | Residential | |||||

| Climate Zone | Code Glazing U-value (W/DegC/m2) |

Code Wall U-value (W/DegC/m2) |

Code Glazing SHGC |

Code Glazing U-value (W/DegC/m2) |

Code Wall U-value (W/DegC/m2) |

Code Glazing SHGC |

| 0A | 2.84 | 0.504 | 0.22 | 3.52 | 0.504 | 0.2 |

| 0B | 2.84 | 0.504 | 0.22 | 3.52 | 0.504 | 0.2 |

| 1A | 2.84 | 0.504 | 0.23 | 3.52 | 0.504 | 0.21 |

| 1B | 2.84 | 0.504 | 0.23 | 3.52 | 0.504 | 0.21 |

| 2A | 2.56 | 0.504 | 0.25 | 3.41 | 0.504 | 0.23 |

| 2B | 2.56 | 0.504 | 0.25 | 3.41 | 0.504 | 0.23 |

| 3A | 2.38 | 0.504 | 0.25 | 3.07 | 0.365 | 0.23 |

| 3B | 2.38 | 0.504 | 0.25 | 3.07 | 0.365 | 0.23 |

| 3C | 2.38 | 0.504 | 0.25 | 3.07 | 0.365 | 0.23 |

| 4A | 2.04 | 0.365 | 0.36 | 2.56 | 0.365 | 0.33 |

| 4B | 2.04 | 0.365 | 0.36 | 2.56 | 0.365 | 0.33 |

| 4C | 2.04 | 0.365 | 0.36 | 2.56 | 0.365 | 0.33 |

| 5A | 2.04 | 0.291 | 0.38 | 2.56 | 0.291 | 0.33 |

| 5B | 2.04 | 0.291 | 0.38 | 2.56 | 0.291 | 0.33 |

| 5C | 2.04 | 0.291 | 0.38 | 2.56 | 0.291 | 0.33 |

| 6A | 1.93 | 0.153 | 0.38 | 2.38 | 0.153 | 0.34 |

| 6B | 1.93 | 0.153 | 0.38 | 2.38 | 0.153 | 0.34 |

| 7A | 1.65 | 0.291 | 0.4 | 2.04 | 0.291 | 0.36 |

| 7B | 1.65 | 0.291 | 0.4 | 2.04 | 0.291 | 0.36 |

| 8A | 1.48 | 0.182 | 0.4 | 1.82 | 0.182 | 0.36 |

| 8B | 1.48 | 0.182 | 0.4 | 1.82 | 0.182 | 0.36 |

| 0A | 2.84 | 0.504 | 0.22 | 3.52 | 0.504 | 0.2 |

| 0B | 2.84 | 0.504 | 0.22 | 3.52 | 0.504 | 0.2 |

Calculated "Baseline effective whole wall" U-values and SHGCs (all assume 40% glazing)

| Non-residential | Residential | |||

| Climate Zone | "Assembly Baseline U-value" (W/DegC/m2) |

"Assembly Baseline SHGC" |

"Assembly Baseline U-value" (W/DegC/m2) |

"Assembly Baseline SHGC" |

| 0A | 1.4384 | 0.088 | 1.7104 | 0.08 |

| 0B | 1.4384 | 0.088 | 1.7104 | 0.08 |

| 1A | 1.4384 | 0.092 | 1.7104 | 0.084 |

| 1B | 1.4384 | 0.092 | 1.7104 | 0.084 |

| 2A | 1.3264 | 0.1 | 1.6664 | 0.092 |

| 2B | 1.3264 | 0.1 | 1.6664 | 0.092 |

| 3A | 1.2544 | 0.1 | 1.447 | 0.092 |

| 3B | 1.2544 | 0.1 | 1.447 | 0.092 |

| 3C | 1.2544 | 0.1 | 1.447 | 0.092 |

| 4A | 1.035 | 0.144 | 1.243 | 0.132 |

| 4B | 1.035 | 0.144 | 1.243 | 0.132 |

| 4C | 1.035 | 0.144 | 1.243 | 0.132 |

| 5A | 0.9906 | 0.152 | 1.1986 | 0.132 |

| 5B | 0.9906 | 0.152 | 1.1986 | 0.132 |

| 5C | 0.9906 | 0.152 | 1.1986 | 0.132 |

| 6A | 0.8638 | 0.152 | 1.0438 | 0.136 |

| 6B | 0.8638 | 0.152 | 1.0438 | 0.136 |

| 7A | 0.8346 | 0.16 | 0.9906 | 0.144 |

| 7B | 0.8346 | 0.16 | 0.9906 | 0.144 |

| 8A | 0.7012 | 0.16 | 0.8372 | 0.144 |

| 8B | 0.7012 | 0.16 | 0.8372 | 0.144 |